Perlite Functional Fillers

For Use in Cementitious Composites

Engineered cementitious composites, also known as strain hardening cement-based composites and bendable concrete, are easily molded mortar-based composites reinforced with short random fibers. Cementitious composites were developed to address the struggles with some building materials, like easy breakage and heavy weight. Benefits include:

- Reduction in dead loads

- Ease of shipping

- Ease of use

- Overall reduced cost

- Greater fire resistance

- Better thermal insulation

There are numerous cementitious composites to choose from, including perlite microspheres, recycled glass, and fly ash cenospheres, to name a few. Today, we’re going to look at how perlite excels as a cementitious composite in lightweight concrete, lightweight building panels, plasters, and joint compound.

Perlite for Cementitious Composites

Perlite is a mineral formed by molten rock, also known as volcanic glass. There are many reasons it is a top choice for cementitious composites:

- Reduces weight and shrinkage of the product

- Improves sandability

- Improves rheology

- Not hollow

- Adsorbs water on the surface, but water will not penetrate the sphere

- Inertness and non-toxicity

- Fire resistance

- Gloss and sheen control

- Available in various sizes and bulk densities

- Does not rot or decay

Perlite Microsphere Specifications

- Bulk density: 0.85 to 0.15g/cm3

- Fire protection: Up to four hours is achievable with the minimum weight and thickness

- Weight: A typical 110 L sack weighs 32 lbs

- Particle size: 500 to 44μm

- Crush strength: 500 to 2000 psi; 3 to 14N/mm2

Considerations

- Amounts of perlite aggregate greater than 30% may have negative effects relating to mechanical strength. Adding sand to the mixture can greatly improve these results.

- Perlite is not recommended for structural or load-bearing uses

Perlite Microsphere Uses as a Cementitious Composite

Lightweight Concrete

As a lightweight concrete, it is used for chimney linings, lightweight floor fills, pool bases, underground pipe and ducting, tank insulation, and more. In addition to providing thermal insulation and noise reduction, it can serve as a supporting envelope. Perlite is also a top choice because it provides monolithic insulation, is permanent, rot-proof, and vermin-proof.

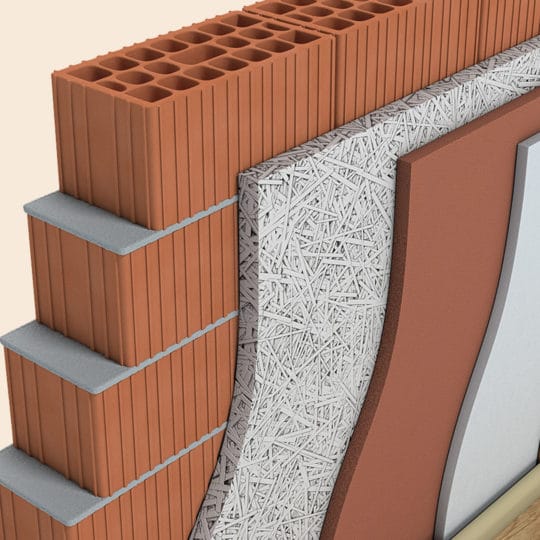

Lightweight Building Panels

Lightweight concrete created with perlite has been used successfully in residential construction to reduce noise transfer through walls, improve fire protection, and reduce strain on structures. Fiber reinforced perlite cement plaster panels using steel studs may be constructed in a fabricating shop or used right on the job site.

Because of its insulating properties, perlite cementitious composites are not recommended over radiant heating panels.

Plasters

Perlite cement-based plaster can be used on new or remodel work, as a basecoat for stucco finishes, and as a substrate for ceramic tile or masonry veneer. It can be applied over metal or wire lath, on top of a cementitious bonding or key coat, or directly over other surfaces prepared with an approved liquid bonding agent. Perlite plaster aggregate mixed with gypsum provides an ideal base coat plaster for interior walls and ceilings and for membrane fireproofing to the underside of floor and roof assemblies or structural steel members.

Compared to sand plaster, it weighs up to 60% less and offers four times as much thermal transfer insulation.

Joint Compound

Joint compounds produced with perlite are lightweight and easy to work with. Perlite also improves the bonding properties and provides greater uniformity. Dicaperl Minerals offers Silane, Siloxane, and Cyclo-siloxane coatings which improve the uniformity between the painted surface of a joint compound and the painted surface of the paper cover sheets of the wallboard. The application of the coatings improve overall paintability as well as in adhesion of the joint compound to wallboard surfaces.

Dicalite Management Group’s Perlite Microspheres

Dicaperl’s industry-leading perlite microspheres are available in a range of densities, degrees of whiteness, and strengths to suit most formulating requirements. Densities range from 4 lbs. per cubic foot up to about 15 lbs. per cubic foot. Proprietary coating microspheres end in product codes 10, 15, and 20.

This special subset of perlite fillers requires advanced manufacturing and classification techniques to produce. Dicaperl is one of the only perlite manufacturers in North America producing perlite microspheres for a variety of industries and applications, from construction and building materials to specialty pharmaceutical and healthcare products.

We’re at the 2019 World of Concrete Show

Whether you’re considering perlite or other cementitious fillers in your application, visit us at Booth S13513 at the World of Concrete show January 22-25 at the Las Vegas Convention Center to learn more about perlite microspheres.

Request Your Free Sample Today.

There are many things to consider when choosing the right cementitious composite for your application. That’s why we’d like to send you a sample of our perlite microspheres. Test them out and see the difference perlite can make. Call us today at 866-728-3303.

Join Our Mailing List

Our blog offers insight and information about new and exciting uses for perlite, diatomaceous earth, and vermiculite deriving from years of research and application. From passive fire resistance to mineral depth filtration, by subscribing to our mailing list, you will receive the latest information surrounding the Dicalite, Dicaperl, and Specialty Vermiculite brands and products.