The Key to Brewing Shelf-Stable Beer

Why 90% of Breweries Filter with Diatomaceous Earth

Like so many events this year, Oktoberfest 2020 was canceled due to COVID-19. While people could not celebrate together in big crowds, they had the opportunity to say “cheers” to this tradition at home with beer purchased from breweries all over the world. Unlike beer on tap that is consumed in a short window of time, beer brewed for cans and bottles has an additional requirement: shelf stability. Diatomaceous earth can be your key to brewing shelf-stable beer. Read on to learn about filtration for crafting beer and why DE is used.

Filtration and Shelf-Stable Beer

When many people think about craft brews, they think of thick brews with a cloudy appearance and maybe a bit of sludge at the bottom. For some enthusiasts, the grit at the bottom of the glass is referred to as dessert; for others, that cloudy beer with particles looks like it’s going to make you sick.

Beer filtration removes yeast, tannins, and some large proteins that eventually settle to the bottom of a barrel, can, or bottle. While safe if consumed, there are a few problems with leaving beer unfiltered in cans or bottles:

- The particles will mix back in with the beer and need to settle again when you move it around the stockroom, it’s delivered to distributors, and your customer brings it home. If consumed or poured without letting it settle again, the consumer will have that hazy beer with particles mixed in with every sip.

- The yeast, tannins, and proteins change the taste of your beer. How long can your brew be left on the shelf or in the fridge before the flavor changes and your customer has an inconsistent experience?

What Is Diatomaceous Earth?

Diatomaceous earth is the naturally occurring fossilized remains of diatoms (a single-celled aquatic algae). It is a near-pure sedimentary deposit consisting almost entirely of silica. Diatomite has a very small particle size, a high porosity, and crystalline structure, making it an excellent filtration medium. It is used as a filter and processing aid in the production of many consumable liquids, including beer.

Why Choose Diatomaceous Earth for Shelf-Stable Beer Filtration

Although there are plenty of newer filtration technologies available to brewers today, diatomaceous earth remains the constant go-to beer filtration aid for many breweries, large and small. As all brewers know, filtering beer is challenging, and using the wrong filter aid can potentially change the taste and look of your beer. Some benefits of filtering beer with diatomaceous earth include:

- Diatomaceous earth is completely natural and a mechanical—not chemical—filtration method.

- It has a high solids holding capacity, allowing for much longer filter cycles (and more solids to be removed) than what would be possible with other filtration methods.

- You can use it to positively change the characteristics of your brew! It’s easy to adjust the filtration and flow, so you have yet another way to fill your beer with a unique personality. It leaves the artistry to you, not the limitations of your filtration method.

More Brewers Choose Diatomaceous Earth for Shelf-Stable Beer Filtration

Although many people think craft breweries do not filter, many of them do—including New Belgium Brewing Company, the fourth-largest craft brewery that delivers their brew all across the United States. Almost all of the brewery’s beer goes through a centrifuge and diatomaceous earth filter to ensure shelf-stability and clarity.

To learn even more about the importance of filtration for brewing, we sat down with Mark Sofio, brewer and co-owner of craft brewery Crowded Castle. “The biggest advantage of diatomaceous earth is that it doesn’t clog. With a membrane, you get clogging that can create problems for you. Diatomaceous earth has the longest history in the industry as the filtering media,” Sofio explained. “We looked at membrane filters, but our consultant recommended diatomaceous earth. Once we figured out the filter, we have been extremely happy.”

Want to learn more from a brewer’s point of view? Read about our interview with Mr. Sofio.

Compatible filters for Diatomaceous Earth

Diatomaceous earth is compatible with a variety of filters you might already have for your brewing process so you can make an easy switch.

Plate: This filter includes a frame, also known as chassis, where quadratic plates and frames are mounted. The plates have filter sheets on both sides, sealing the plates and frames against each other. Pre-coating and body feed are used to form filter cakes. After the filtration cycle, the diatomaceous earth can be spray-washed so the sheet can be used again.

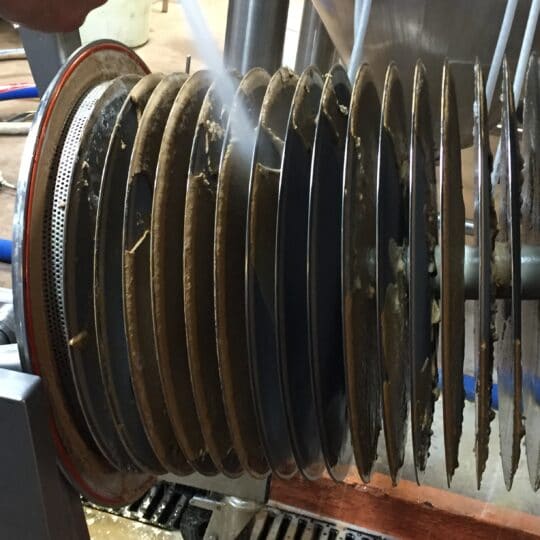

Leaf: This filtration method includes an upright cylinder with many round filter elements arranged in a hollow shaft. A fabric made with chrome-nickel steel is the base for building filter cakes. This method is known for its flexibility and ability to maintain the filter cake.

Candle: Candle filters are cylindrical, upright conical pressure tanks. They hold hundreds of candles fixed to a top plate which is then suspended in the housing. Diatomaceous earth is coated around the candle cartridges. This method is frequently used in high-production breweries.

Choose Dicalite Management Group for your Mineral Filtration Needs.

The mineral experts at Dicalite Management Group know the ins and outs of using diatomaceous earth and perlite for beer filtration. We know you’ll love it too, so we’d like to send you a free sample. Our customer service representatives located at our plants are standing by, and our technical experts are anticipating your call. Call us today at 866-728-3303 for your free sample and to see for yourself what makes Dicalite Management Group a customer-first industrial minerals company.

If you’d like to learn more about using minerals for filtration, download our free e-book A World of Filtration Experience today.

Join Our Mailing List

Our blog offers insight and information about new and exciting uses for perlite, diatomaceous earth, and vermiculite deriving from years of research and application. From passive fire resistance to mineral depth filtration, by subscribing to our mailing list, you will receive the latest information surrounding the Dicalite, Dicaperl, and Specialty Vermiculite brands and products.