Microspheres

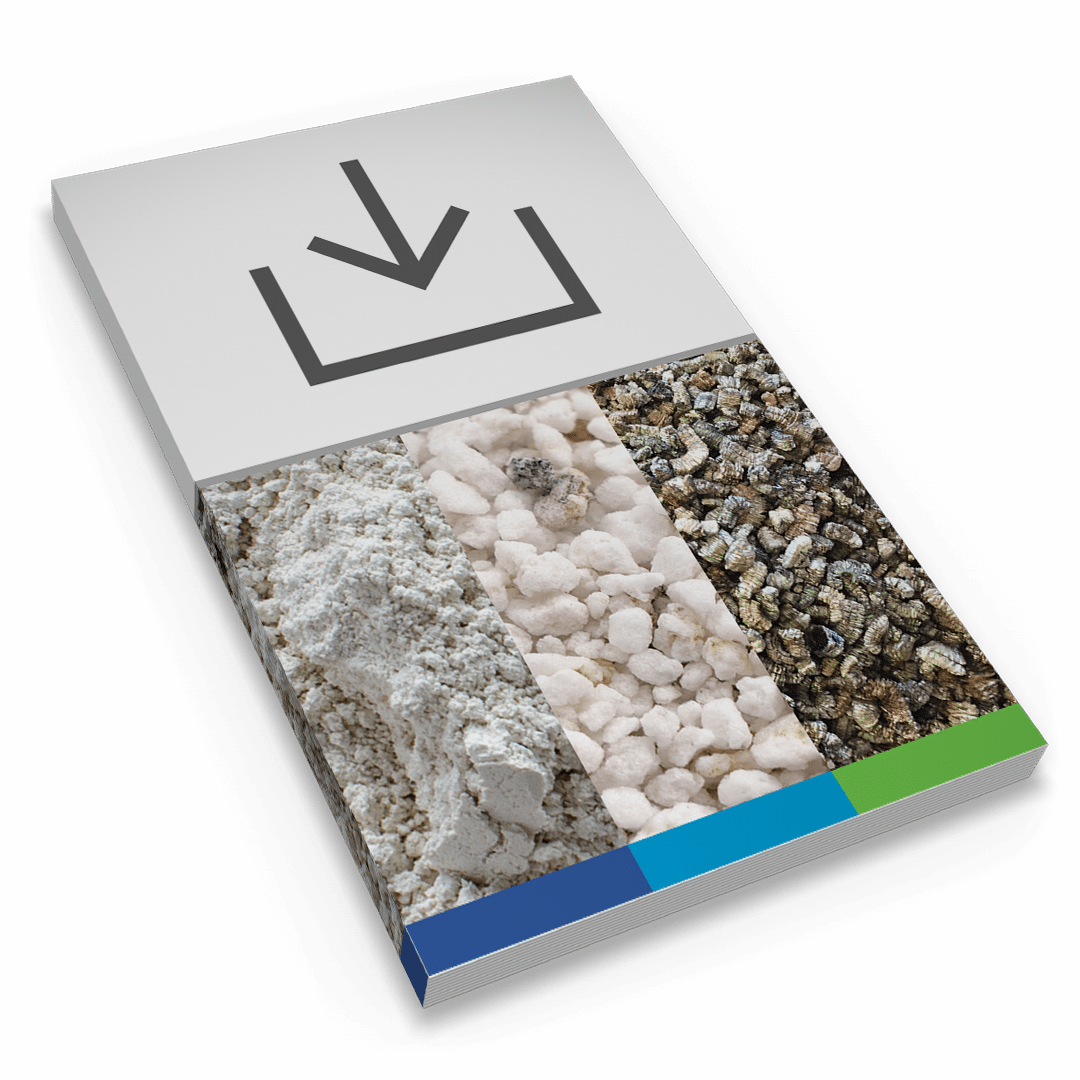

Dicaperl Perlite Microspheres provides a cost-effective and density-reducing filler for water-or resin-based applications in the construction industry. A single gram of Dicaperl HP perlite microspheres contains millions of particles!

Dicaperl Microspheres are composed of many cells, or bubbles, which look like honeycomb under a microscope. They may contain nearly perfect spheres and a multitude of other similar shapes depending upon the grade produced. We’ve also developed an exclusive coating technology that allows application of multi-functional coatings to many of our fillers, adding another dimension to their usage. This special coating technology is a is a further indication of the strength of our company’s commitment to producing premium filler products.

The benefits of using perlite microspheres as a functional filler include:

- Absorbs water on the surface

- Fire resistance

- Gloss and sheen control

- Improves rheology

- Improves sandability

- Inertness and non-toxicity

- Reduces weight and shrinkage of product

Why Choose Dicaperl Microsphere functional fillers?

Our microspheres start with perlite ore that is mined from our Socorro facility. Mining our own raw materials means that quality control is maintained upstream of our expansion facilities, guaranteeing the best product for our customers.

Once our perlite ore is shipped to one of our perlite microsphere expansion facilities across the United States, the production of the finished Dicaperl Microspheres begins. Using systems and technology developed in-house from decades of experience, we produce the products on time and with repeatable quality control specifications.

Dicaperl HP Series Perlite microspheres are available in grades ranging from 40μ to over 200μ, with or without surface coatings. Three different types of proprietary hydrophobic coatings can be applied the Dicaperl Microspheres, imparting characteristics that enhance the capabilities and functionality of the product.

Perlite Coated Microspheres

| Product TDS | MPD (um) | Application |

|---|---|---|

| HP120, HP125, HP135 | 300-330 | Cement Boards, Stucco, and Texturing |

| HP220, HP225, HP235 | 110-125 | Cement Boards, Siding, Stucco, and Texturing |

| HP920, HP925 | 80-90 | Cement Boards, Joint Compounds, Plastics Fillers, and Spackling Compounds |

| HP935, HP1520, HP1525 | 80-90 | Cement Boards, Joint Compounds, Plastics Fillers, and Spackling Compounds |

| HP1520, HP1525, HP1535 | 70-80 | Cement Boards, Joint Compounds, Plastics Filters, and Spackling Compounds |

| HP2020, HP2025, HP2035 | 60-70 | Cement Boards, Joint Compounds, and Plastic Fillers |

| HP2320, HP2325, HP2335 | 55-60 | Fine Filter Applications and Joint Compounds |

Perlite Uncoated Microspheres

| Product TDS | MPD (um) | Application |

|---|---|---|

| HP100 | 300-330 | Cement Boards, Stucco, and Texturing |

| HP200 | 110-125 | Cement Boards, Siding, Stucco, and Texturing |

| HP900 | 80-90 | Cement Boards, Joint Compounds, Plastics Fillers, and Spackling Compounds |

| HP1500 | 70-80 | Cement Boards, Joint Compounds, Plastics Filters, and Spackling Compounds |

| HP2000 | 60-70 | Cement Boards, Joint Compounds, and Plastic Fillers |

| HP2300 | 55-60 | Fine Filter Applications and Joint Compounds |

Perlite Microspheres are Used in a Variety of Applications

- Cement additives

- Grout

- Caulk

- Flooring compounds

- Joint compound

- Automotive putty

- Marine putty

- Composites

- Paints

- Coatings

- Plastics

- Top coats

- Prime paints

- Thermoplastics

- Resins

- Cosmetics

Why Dicaperl Microsphere Functional Filler?

Dicaperl HP Series Perlite microspheres are available in grades ranging from 40um to over 200um, with or without surface coatings. Three different types of proprietary hydrophobic coatings can be applied the Dicaperl Microspheres imparting characteristics which enhance the capabilities and functionality of the product.

Our microspheres start with perlite ore mined from our Socorro facility to ensure quality and consistency. As much quality control as possible is accomplished upstream of the expansion facilities, ensuring the best possible product for our customers.

Once our perlite ore is shipped to one of our five perlite microsphere expansion facilities located across the United States, the production of the finished Dicaperl Microspheres begins. Using systems and technology developed in-house from decades of experience ensures we produce the products on time and with repeatable quality control specifications.

Contact Us

Contact us today to learn how we can help your processes, buy direct or from a distributor, or request a free sample of our products. We look forward to hearing from you.